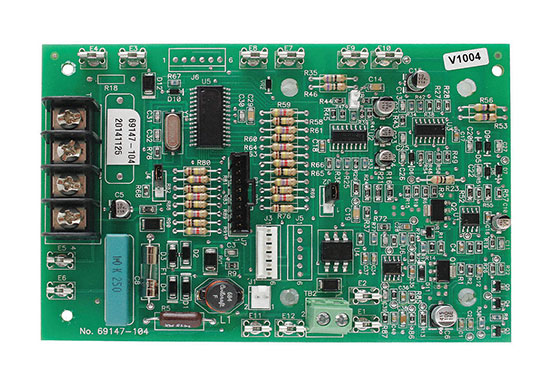

SMT (Surface Mount Technology), is the most popular technology and process in the electronics assembly industry.

AOI is the abbreviation of Automatic Organic Inspection.It uses high speed and accurate vision processing technology to detect various mistake-assembly and solder defects on PCB.

SPI stands for Solder Paste Inspection, it is the inspection and verification and control of solder paste quality for the printing process.

The role of AOI and SPI in SMT processing

1.Quality control: Cover some defects that cannot be detected manually, including (original part offset, component less tin, solder joint short circuit, component reverse, component misload, component deformation, component leakage, component erection.)

2.Process control: real-time generation of statistical charts, the type of failure, frequency and other information real-time feedback to the production department, so that the production department in a timely manner to find the production process and correct the problem in a timely manner. As soon as possible, in order to minimize the loss of time and materials.

3.Process parameters and other validation: For a new special processing veneer, from printing process parameters to reflow process parameters, all need to be carefully modulated, whether the settings of these parameters are reasonable, ultimately depends on the quality of the solder, this process must be tested several times to achieve. AOI provides an effective means of verifying test results.

SPI is used after the printing machine for quality inspection of solder printing and verification and control of the printing process. SPI plays a considerable role in the whole SMT. And AOI is divided into two kinds of furnace before and after the furnace, the former for device placement inspection, the latter for the detection of solder joints.

The two functions are different, SPI inspection solder paste printing, AOI in the furnace before the inspection of the stability of the cracked parts, in the furnace after the inspection of the solder quality, etc.