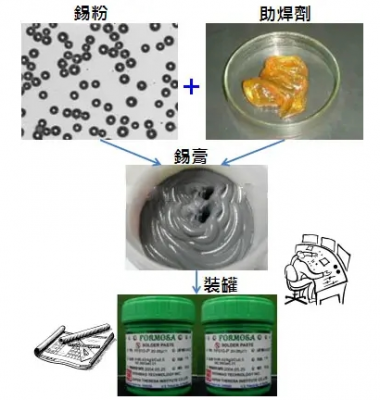

SMT placement process in the welding process, can purify the weld metal and welding surface, help welding substances called flux, referred to as flux. Flux is an indispensable process material in the soft brazing process, in the wave soldering and manual soldering process using liquid flux, flux and solder are used separately. In the reflow process, the flux is used as an important part of the solder paste.

SMT processing soldering quality is also bad, in addition to the quality of the solder alloy, components, pcb, welding process, but also with the performance of the flux, flux selection has a very important relationship. The next for you to introduce SMT chip processing for flux requirements.

SMT chip processing for flux requirements

1. The appearance of the flux should be uniform, transparent, without precipitation or stratification, and without foreign matter. The flux should not emit toxic, harmful or Yukon strong irritating odor gas and denser fumes to help protect the environment. Its color should not change during the effective storage period.

2. The viscosity and density are smaller than molten solder and can be easily displaced. The density of flux can be diluted with solvent and should be 0.80-0.95g/cm3 at 23 degrees C. No-clean flux should be within (100±1.5 )% of its nominal density.

3. surface tension than the solder is small, wetting expansion rate faster than the molten solder, expansion rate of > 85%.

4. melting point is lower than the solder, before the melting of the solder, the flux can give full play to the fluxing effect.

5. non-volatile content should not be greater than 15%, welding does not produce welding bead spatter, does not produce toxic gas and strong irritating odor.

6. The surface of the residue after welding should be non-sticky and non-sticky, and the chalky powder on the surface should be easily removed.

7. No-clean flux requires solid content <2.0%, no halide, less residue after soldering, no moisture absorption, no corrosion, good insulation performance, insulation resistance >1*10 square ohm.

8. Water cleaning, semi-water cleaning and solvent cleaning fluxes require easy cleaning after soldering.

About Grande

Grande PCBA specializes in providing overall PCBA electronic manufacturing services, including upstream electronic components procurement to PCB production and processing, SMT placement, DIP plug-in, PCBA testing, finished product assembly and other one-stop services.

The company gives full play to its competitive advantages in scale procurement and quality control, and has signed long-term cooperation agreements with many domestic and global electronic component manufacturers to ensure the quality and stable supply of raw material sources and transfer the benefits to customers.

Long-term procurement advantages in IC, resistors, capacitors, inductors, diodes and other components can greatly save customers’ inventory costs, improve production turnaround efficiency and save time. At present, we provide PCBA processing service for customers in USA, UK, Japan, Russia, France, Canada, Australia, Romania, Switzerland and other countries and regions.

We provide PCBA processing services, starting from PCB board fabrication, our own PCB manufacturer (with extremely strict TS16949 certification for the automotive industry), focusing on the quality of the board and PCBA quality control system.

Due to decades of experience in procurement of electronic components, we maintain long term cooperation with large brands to ensure the original packaging of components and procurement channels. In the encapsulation process of components, we choose Senju and Loctite solder paste to ensure the reliability of the soldering, with automatic printing machine, Panasonic high-speed placement machine, upper and lower eight temperature zone reflow soldering, AOI automatic optical detector, etc., which can effectively ensure the reliability and quality of the electronic packaging process.

In addition, the perfect management process of IPC, IPQC, OQA, etc., with clear job responsibilities and strict implementation of IPC electronic assembly acceptance standards. Regarding PCBA testing, we have professional engineers to perform 100% batch testing using various test stands, including pathway, noise, amplitude, signal, temperature, humidity, drop or execute customer’s detailed test program. All efforts aim to be a fine PCBA processing manufacturer.