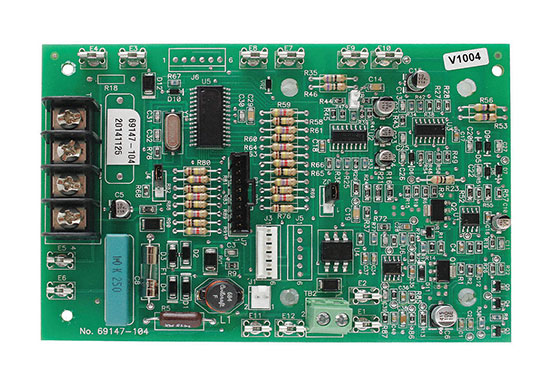

Due to the complex operating environment of industrial PCBA , the failure rate is higher than that of ordinary circuit boards. During maintenance, it is necessary to understand the vulnerable parts on the circuit board. So, which parts of the industrial PCBA board are most prone to failure?

The Most Fault-Prone Parts of Industrial PCBA

l. The place where the design is unreasonable

The first is the problem of heat dissipation. a great number of circuit board damages are caused by poor heat dissipation design; The second is that the copper foil wire of the circuit board is designed too thin, which is easily blown due to over current, making the motherboard unable to work.

2. Frequently used places

For instance, the drive motor of the circuit board, the rotating shaft, the switch tube of the switching power supply, the commonly used buttons of the operation panel, etc.

3. Components with heavy load, high power and high working voltage

The power supply, drive circuit, power control device and other components of the circuit board are generally close to the heat sink. If the protection measures are not enough and the heat dissipation is not good, it is easy to become the first place to fail.

4. The protection circuit

The precious chips or components on the circuit board are equipped with protective equipment. Once the circuit board is abnormal, the first problem is these protection circuits.

5. The interface of the inline seat, the connector and the cable

Such as the poor contact between the board and the slot, the poor contact between the wire plug and the terminal, and the virtual soldering of components.

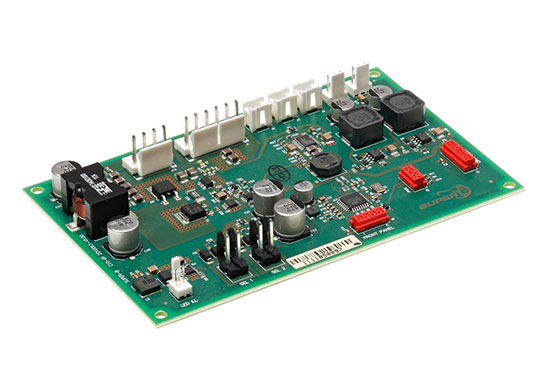

Grande PCBA Capability

1. Maximum Board: 310mm*410mm(SMT);

2. Maximum Board Thickness: 3mm;

3. Minimum Board Thickness: 0.5mm;

4. Minimum Chip Components: 0201 package or parts above 0.6mm*0.3mm;

5. Maximum Weight of Mounted Components: 150 grams;

6. Maximum Component Height: 25mm;

7. Maximum Component Size: 150mm*150mm;

8. Minimum Pin Spacing: 0.3mm;

9. Minimum Spherical Component (BGA) Spacing: 0.3mm;

10. Minimum Spherical Component (BGA) Ball Diameter: 0.3mm;

11. Maximum Components Placement Accuracy (100QFP): 25um@IPC;

12. SMD Capacity: 3-4 million points/day.

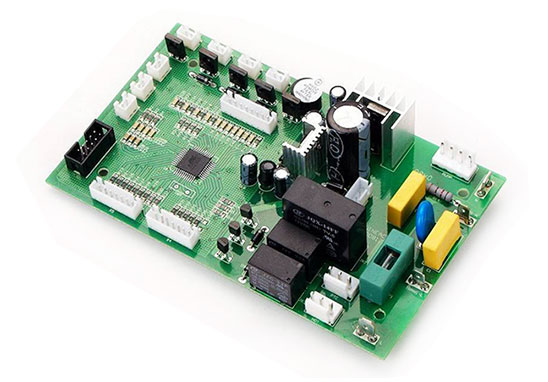

Grande PCB Assembly Advantages

1)Strength Guarantee

2)Quality Assurance With High Cost Performance

3)Rich Electronic Products SMT Soldering Experience With Stable Delivery

4)Strong Maintenance Ability & Reliable After-Sales Service