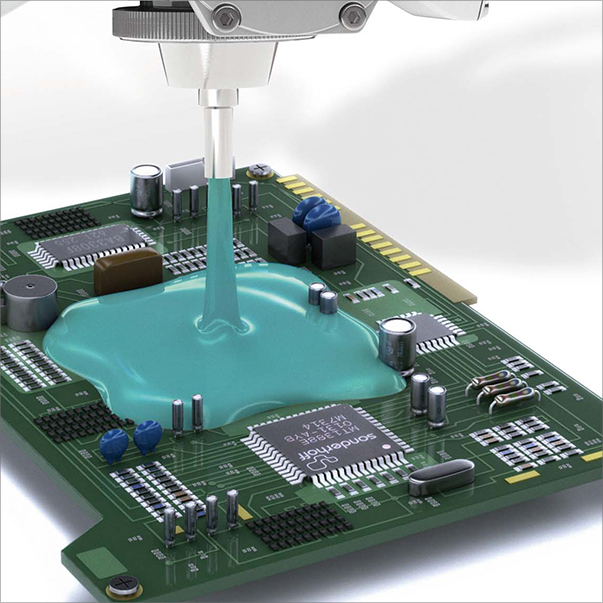

As the size of the electronic components of the PCBA circuit board is getting smaller and smaller, and the density is getting higher and higher; The influence on PCBA is also increasing, so we put forward higher requirements for the reliability of PCBA of electronic products. PCBA circuit board three-proof potting material can effectively achieve the protection effects of insulation, moisture-proof, anti-leakage, shock-proof, dust-proof, anti-salt spray, etc. Thereby improving the reliability of the circuit board, increasing its safety factor, and effectively delaying the service life.

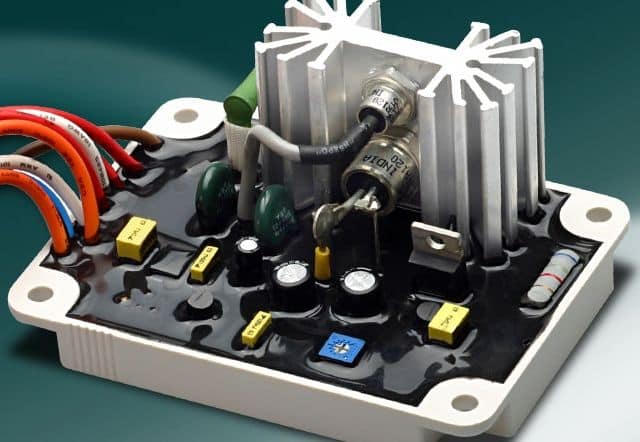

Application of Potting Material

PCBA circuit board potting material is widely used in high-tech fields, such as high-end circuit boards in automobiles, home appliances, military electronics, aerospace, medical electronics, etc., which can improve product quality of PCBA circuit boards and effectively reduce rework.

In addition, the rise of emerging industries, the widespread use of electric vehicle charging piles, and unmanned aircraft have further expanded the use of conformal paint. At present, it has become a major trend to apply conformal paint on PCBA for protection.

Function of Potting Material

The potting material is used to protect PCBA circuit boards and related equipment from environmental erosion, whose function is mainly to improve the reliability of products, especially in harsh operating environments.

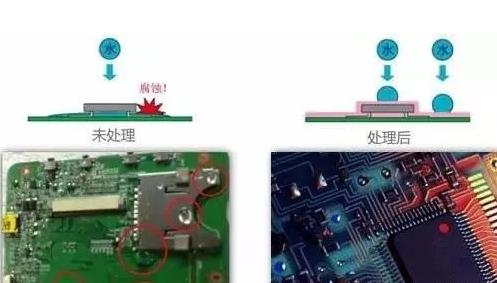

The potting material protects electronics from external elements such as extreme heat, humidity, moisture and dust. It also protects electronics from internal factors such as corrosion, whisker growth and short circuits within the system. In short, the potting material is equivalent to an insulating layer, which ensures that different components can operate normally and avoids premature failure of the PCB.

Operating requirements for brushing PCBA potting material

- Brushing potting material should be carried out in a separate room, but it cannot be completely sealed, which must have good ventilation facilities.

- Smoking, eating and drinking are prohibited in the operation room, and alcoholic beverages are not allowed before operating.

- Wear masks or gas masks, rubber gloves, chemical protective glasses and other protective equipment during operation to avoid harm to the body. This also depends on the potting material products selected. If it is a benzene-containing product, you should pay great attention to protection. And fire protection, and if it is a TIS-NM environmentally friendly potting material product, the safety is much higher, and there is no risk of burning.

- After the work is completed, the used utensils should be cleaned in time, the tools and equipments should be sorted and tested, and the containers with potting material should be tightly covered.

- The workplace should be clean and dust-free, no dust flying, and no unrelated personnel should be allowed to enter.

- Tools and equipments should be fully grounded, and electrostatic protection measures should be taken.

- Do not overlap the PCBA during operation; And the PCB board should be placed horizontally.

- Before each batch of raw materials is used, a small sample curing test (3-5PCS) should be done.

- Clean and bake the board. Dust, moisture and oil must be removed from the surface of the object to be coated so that the potting material is able to fully exert its protective effect. Thorough cleaning ensures that corrosive residues are completely removed and that the conformal coating adheres well to the board surface. Baking conditions: 60°C, 10-20 minutes, it is better to apply while hot after taking it out of the oven.

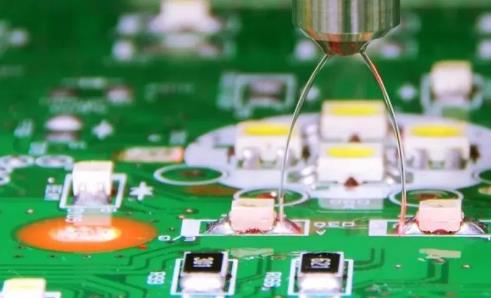

- When brushing, the board should be placed as flat as possible. There should be no dew after brushing. The brushing should be flat and there should be no exposed parts. It is appropriate between 0.1-0.3mm.

- Before brushing and spraying, ensure that the diluted product is fully agitated and left for 2 hours before brushing or spraying. Using a high quality natural fiber brush, lightly brush and dip at room temperature. If a machine is used, the viscosity of the paint should be measured (with a viscosity agent or flow cup), and a diluent can be used to adjust the viscosity.

- The circuit board assembly should be immersed in the paint tank vertically. The connector should not be immersed unless carefully covered, and the circuit board should be immersed for 1 minute until the bubbles disappear, and then slowly taken out. A uniform film will be formed on the surface of the circuit board. Most of the paint residue should be allowed to flow from the board back to the immersion filmer. TFCF has different coating requirements. The immersion speed of circuit boards or components should not be too fast to avoid excessive bubbles.

- When using it again after dipping, if there is crusting on the surface, remove the skin and continue to use it.

- After brushing, lay it flat on the bracket and prepare to cure. The method that needs to be heated is to accelerate the curing of the potting material. If the potting material surface is uneven or contains air bubbles, curing in a high temperature oven should be left at room temperature for an additional time to allow the solvent to flash out.

Technical requirements for brushing PCBA potting material

- The potting material protection must be tested, qualified and thoroughly cleaned before PCB Assembly.

- The brush used should be kept clean, and it is forbidden to use it for other operations; When applying the potting material to the brush, be careful not to drip into the components that do not need to be coated; And the brush should be cleaned with thinner after use.

- The coating layer should be transparent and cover the PCB board and components evenly, with uniform color and consistency.

- The process steps are: Brushing A surface → A Surface Drying → Brushing B surface → Curing At Room Temperature

- Spraying thickness: Spraying thickness is 0.1mm—0.3mm (dry film thickness is generally 30-100UM)

- All coating operations should be carried out under the conditions of not lower than 16°C and relative humidity lower than 75%. As a composite material, PCB will absorb moisture. If it is not dehumidified, the potting material cannot fully protect it. Pre-drying and vacuum drying can remove most of the moisture.

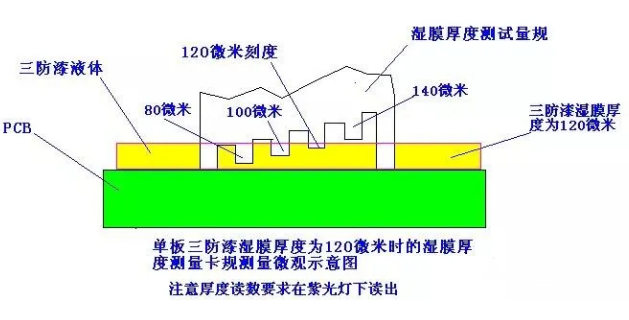

Thickness Test Method:

1. Dry film thickness measuring tool: A. Micrometer (IPC-CC-830B); B. Dry film thickness gauge (iron base)

2. Wet film thickness measurement: The thickness of the wet film can be obtained by the wet film thickness gauge, and then the thickness of the dry film can be calculated by the proportion of the solid content of the glue.

Many circuit boards undergo cross-sectional inspection after selective coating to ensure potting material coverage and thickness are met.