In order to facilitate the assembly of the printed circuit board (PCBA), fiducial mark will be designed on the PCB board. Do you konw? The requirements and specifications of fiducial mark In PCB Design?

What Is PCB Fiducial Mark?

Circuit board fiducial mark refers to determining the specific position of the PCB via in the PCB design process, which is a super important link in the PCB design process. After all, the function of the fiducial mark is the processing benchmark when the printed circuit board is maufactuered. There are various positioning methods for PCB fiducial mark, mainly in the light of different positioning accuracy requirements. The fiducial mark on the printed circuit board should be represented by special graphic symbols. When the requirements are not high, larger mounting holes in the printed circuit board can also be used instead.

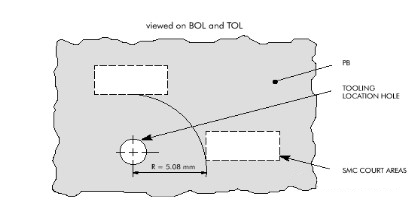

In order to facilitate the fixing of the board during drilling and milling of the printed circuit board, as well as to facilitate online testing, plenty of circuit board manufacturers want users to design three non-metallized holes on the PCB. And the fiducial mark is usually designed as non-metallized holes, and the drilling diameter unit is basically mm. If the board surface is tight, at least two fiducial marks should be placed and placed diagonally. If you want to produce panel board, you can also regard the whole panel board as a PCB, and the entire panel board only need fiducial marks. If the user does not place it, the circuit board manufacturer will automatically add it without affecting the circuit, or use the existing non-metallized holes in the board as fiducial marks.

Positioning Fiducial Mark Method

Device hole interface devices and connectors are mostly plug-in components. The diameter of the through hole of the plug-in device is 8 to 20 mil larger than the diameter of the pin, and the tin penetration is good when soldering. It should be noted that there is an error in the aperture of the circuit board factory. The approximate error is ±0.05mm. Every 0.05mm is a drill. The diameter is more than 3.20mm, and every 0.1mm is a drill. Therefore, when designing the aperture of the device, the unit should be converted into millimeters, and the aperture should be designed to be an integer multiple of 0.05. The plate manufacturer sets the size of the drilling tool according to the drilling data provided by the user. The size of the drilling tool is usually 0.1-0.15mm larger than the forming hole required by the user. Less is better. If it is a crimping device, the aperture should not be enlarged, it should be designed according to the recommendations of the data, and which are the crimping devices should be explained in the board making instructions, so that the circuit board manufacturer can try to control the error during the board making process and avoid some unnecessary trouble.

PCB Design Fiducial Mark Requirements & Specifications

Drilling types are divided into metallized holes and non-metallized holes. There is copper sinking in the hole wall of the metallized hole, which can play a conductive role and is represented by PTH. There is no copper sinking in the hole wall of the non-metallized hole, which can not play a conductive role, which is represented by NPTH. The difference between the outer diameter and the inner diameter of the metallized hole diameter should be greater than 20mil, otherwise the soldering ring of the pad is too small to be processed, and it is not conducive to soldering. If conditions permit, the aperture can be designed to be the radius of the pad. The maximum drilling diameter of metallized holes is 6.35mm, and the maximum drilling diameter of non-metallized holes is 6.5mm. The metallized hole should not be designed on the outline, and the edge of the hole should generally be greater than 1mm from the outline. Heavy holes while drilling are easily able to damage the drill bit, so it should be avoided as much as possible. Holes that do not require soldering and have no electrical characteristics can be designed as non-metallized holes. Non-metallized holes do not need to be designed with pads. The edge of the hole is at least 1mmo away from the circuit or copper foil. Drilling can be divided into circular holes and rectangular holes according to the shape. Most of the drilled holes are round holes, and rectangular holes are drilled multiple times by the drill bit according to the prescribed procedure. Therefore, it is best to design the rectangular hole to be twice as long as the width, and the width is not less than 0.8mm, and the rectangular hole should be designed as little as possible.

PCB Fiducial Mark Requirements

The development of the PCB design industry has become mature, so the requirements for PCB fiducial marks are also rather perfect. The fiducial mark requirements are as follows:

1. At least two fiducial marks must be set on the diagonal of the board.

2. The standard diameter of the fiducial mark is 3.2mm_+0.05mm.

3. The following preferred apertures can also be used for the veneer of different products of the enterprise: 2.8mm±0.05mm, 3.0mm±0.5mm, 3.5mm±0.5mm and 4.5mm±05mm. For different boards of the same product (such as the DT board and PP board of ZXJ10), if the external dimensions of the PCB are the same, the positions of the positioning holes must also be unified.

4. The fiducial mark is a light hole, that is, a non-metallized through hole (except for the RF board).

5. If the existing installation holes (except the buckle installation holes) meet the above requirements, there is no need to set additional fiducial marks.

Some Common Specifications & Accuracy Requirements For Fiducial Marks

1. The diameter error range of the fiducial mark is generally within 0.01mm. If the PCB manufacturing room has a large error, it will cause poor contact of the probe and inaccurate alignment of the interface connector automatic mechanism.

2. Requirements for the diameter of the fiducial mark: Try to be below 3mm, so that the positioning column will not be deformed, and it is not easy to operate if it is too large.

3. The distance between the fiducial mark and the PCB network: More than 1MM, so that the installation operation is not easy to short-circuit, and it will not cause damage to the product line.

4. Type of fiducial mark: The fiducial mark is generally a mechanical control that requires no copper sinking, so that it is not connected to the circuit on the board and has higher precision.

5. The layout of the fiducial mark: It need to be on the four corners or diagonal lines of the PCBA, so as to form a multi-point surface positioning, the positioning is accurate, and the farther the distance, the better.

6. The distance between the fiducial mark and the test point should be at least 2mm to prevent false short circuit during the test.

7. The distance between the fiducial mark and the edge of the board is at least 2mm, which is not easy to break while ensuring the strength of the PCBA.