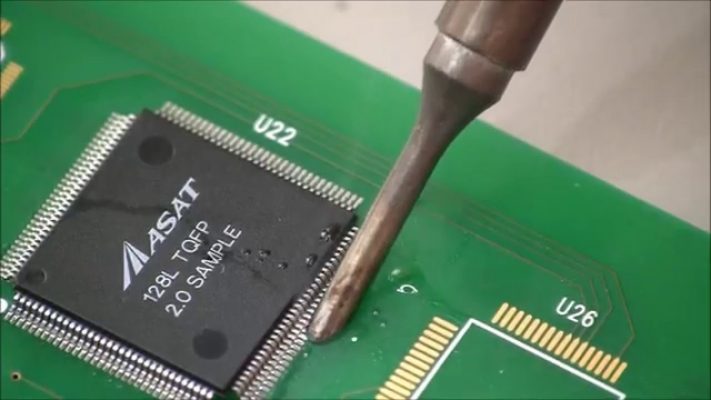

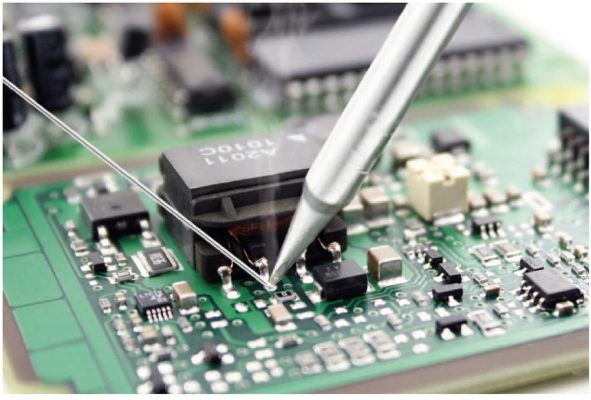

In PCB Assembly, some customers only need require and place sample orders, such as only 2-3 pcs sample PCBA. In this case, if the board is not complicated or customer not particularly required, manual soldering usually will be adopted considering saving cost for the customer. The difficulty of Manual Soldering is to mount ICs, especially ICs with high integration.

IC, Integrated Circuit, the industry generally divides its types by IC package form. Traditional ICs include SOP, SOJ, QFP, PLCC, etc., while newer ICs include BGA, CSP, FLIP CHIP, etc. These component types come in various shapes due to the number and size of PINs and the spacing between the pins. The chip component packaging form is a semiconductor device packaging form.

SMT involves a wide variety of components and styles, many of which have formed industry standards, mainly some chip capacitors and resistors; Many are still changing, especially IC, and the changes in packaging forms are endless, making it dizzying.

In the assembly of hand mounting, the difficulty of IC mounting is relatively huge. After all, ICs generally have a large number of pins, which requires our SMT assembly personnel to be patient and operate in strict accordance with the processing requirements to ensure good soldering quality is almost same as machine assembly mounting boards. For instance, due to the high internal integration, it is easy to be damaged by overheating. Generally speaking, the temperature of mounting IC cannot be higher than 200 ℃.

Precautions For Manual Mounting IC

1. The soldering time should be as short as possible, generally no more than 3s.

2. It is best to use an electric soldering iron with a constant temperature of 230 degrees.

3. Anti-static treatment should be done on the SMT Assembly workbench.

4. Choose some sharp and narrow soldering iron tips, and the soldering will not touch the adjacent endpoints.

5. During Manual SMT Assembly, do not remove the preset short lines before soldering the CMOS circuit.

6. Don’t scratch the gold-plated circuit pins with a knife, just use alcohol or a drawing eraser.