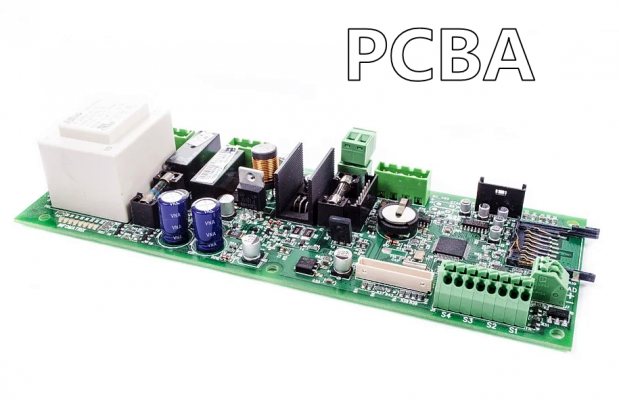

The basis of SMT Assembly is PCB, that is, Printed Circuit Board, which are distinguished by the number of layers, such as double-sided boards and four-layer boards. At present, up to 48 layers can be achieved. Speaking from a technical point of view, the number of layers has unlimited possibilities in the future. Some supercomputers have nearly a hundred layers. However, the most common number of layers in medical electronic PCBA or automotive electronic PCBA is usually 2 or 4 layers. If you want to know how to choose the number of layers of the PCB reasonably, please read the following introduction about the difference between the 2 Layer board and 4 layer board in SMT Assembly before making a decision!

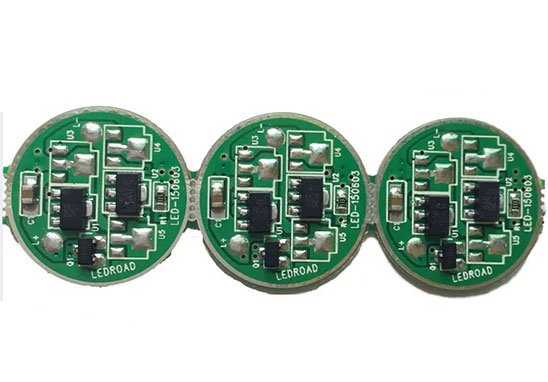

2 Layer Board

Compared with the four-layer board, the double-sided board is easier to use due to its simple design. Although not as simple as single-sided panels, they are as simple as possible without sacrificing double-sided input capabilities. The reduced complexity leads to the same reduced price tag, but this means that there are fewer possibilities compared to a four-layer board. However, as the most commonly used circuit board in the industry, its significant advantage is that there is no signal propagation delay.

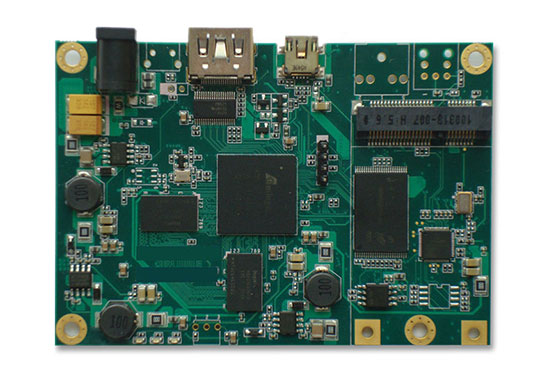

4 Layer Board

Four-layer boards have a larger surface area than double-sided boards, increasing the possibility of more layout. Therefore, they are terribly suitable for more complex equipment. Due to their complexity, production cost will be higher and development will be slower. They are also more likely to have propagation delay or mutual influence, so reasonable design is very important.

What’s the purpose of layers?

The most important layer in the PCB that is the copper foil signal layer, which is the name of the PCB. Although the double-sided board has two signal layers, while 4-layer PCB has four. These signal layers are used to connect to other electronic components in the device. Between these layers is an insulating layer or core, which is added between the signal layers to give its structure. In the four-layer board, there is also a solder mask layer, which is applied on top of the signal layer. This prevents copper traces from interfering with other metal components on the PCB. They also have a silk screen layer to add numbers to different components to make them easier to lay out.

If you are looking for Turnkey PCBA Service / EMS Company, then Grande is your best choice. We provide One- Stop Service like PCB Fabrication, Components Procurement, PCBA Manufacturing, Function Test, even Final Box Assembly, etc.