PCB is an important electronic component and a carrier for the electrical interconnection of electronic components. So many people are curious how the price of PCB is calculated. Now, let’s analyze the factors that affect the price of PCB together!

Factors Affecting PCB Price:

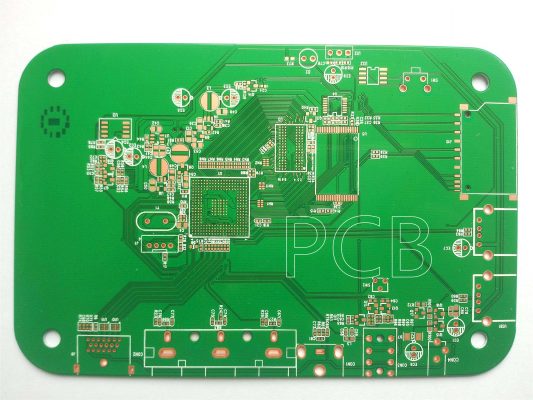

1. Material of the PCB circuit board

Take an ordinary double-sided circuit board as an example. Board materials typically include FR-4, CEM-3, with thicknesses from 0.6mm to 3.0mm, and copper thicknesses from 0.5 oz to 3 oz. Solder mask (ink), there is a certain price difference between ordinary thermosetting ink and photosensitive green ink.

2. Production process used for printed circuit boards

Different production processes lead to different costs. For example, gold-plated circuit boards and tin-sprayed gongs (milling) and (stamping), and using printed circuits and dry film circuits have different costs.

3. The difficulty of PCB circuit boards

Even if the materials are the same, the process is the same, and the difficulty of the PCB itself will still result in different costs. If there are 1000 small holes on both boards, one board has holes larger than 0.6mm in diameter and the other board has holes smaller than 0.6mm, this will result in different drilling costs. For instance, two types of circuit boards are the same, however, the line width and line spacing are different, one type is larger than 0.2 mm, and one type is smaller than 0.2 mm, it will also lead to different production costs because of difficult board scrap rates higher, the cost will inevitably increase.

4. Different customer needs also lead to different prices

The level of customer demand will directly affect the output of the factory, such as, a factory requires a 98% pass rate for class1 according to IPC-A-600E, but may only have a 90% pass rate according to class3 requirements.

5. Different PCB circuit board manufacturers

Even if the same product is made by different manufacturers with different process equipment and technical level, the result is different cost. Today, many manufacturers produce gold-plated plates because of the simple process and low cost. However, when some manufacturers produce gold-plated boards, the resulting cost will increase when they are scrapped. So they prefer to produce tin-sprayed boards, because tin-sprayed boards lower than gold-plated boards.

6. Different payment methods

At present, PCB board manufacturers usually adjust the PCB price according to different payment methods, ranging from 5% to 10%.

7. Different regions

Currently, geographically in China, prices increase from south to north, and there are some differences in prices in different regions.

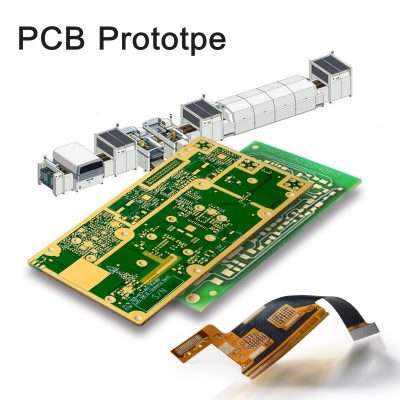

Grande PCB manufacturing advantages

1.Mass Production: 2 to 14 layers Sample Production:14 to 22 layers;

2.Minimum Line Width/Spacing: 3mil/3mil BGA spacing: 0.20MM

3.Minimum aperture of finished product: 0.1mm Size: 610mmX1200mm

4.Solder Mask (Ink): Japan Tamura, Taiyo, Futoken;

5.FR4 Brand: Shengyi, Kingboard, Haigang, Hongren, Guoji, Hazens, South Asia,

(Shengyi S1130/S1141/S1170), Tg130℃/ Tg170℃ Tg180℃ and other high TG plates)

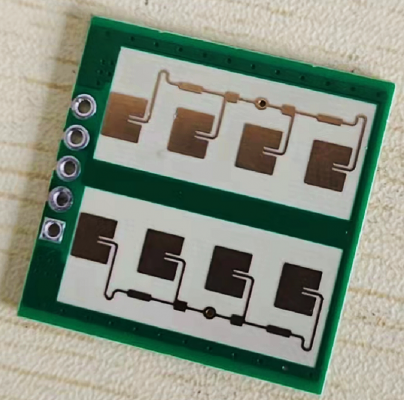

6.High Frequency Board: Rogers (Rogers), Taconic, ARLLON;

7.Surface Finish Technology: Spray tin, lead-free spray tin, immersion gold, full board gold plating, plug gold plating, full board thick gold, chemical immersion tin (silver), anti-oxidation (OSP) blue glue, carbon oil

Grande is a professional PCB manufacturer with more than 20 years of professional experience, and its board manufacturing capabilities cover rigid circuit boards, FPC, Rigid-flex PCB, etc. If you have any printed circuit board processing needs, welcome to contact us.